What Are the Materials Used in Power Cables?

A Practical Guide to Their Pros and Cons

When you flip a switch or plug in your device, you likely don’t think about the power cables behind the scenes. But the materials inside those cables are crucial to how efficiently and safely electricity gets where it needs to go.

In this blog, we’ll break down the key materials used in power cables—from the metal cores to the outer insulation—and explore their respective advantages and disadvantages. Whether you're an engineer, installer, or just curious, this guide gives you a clear, practical overview.

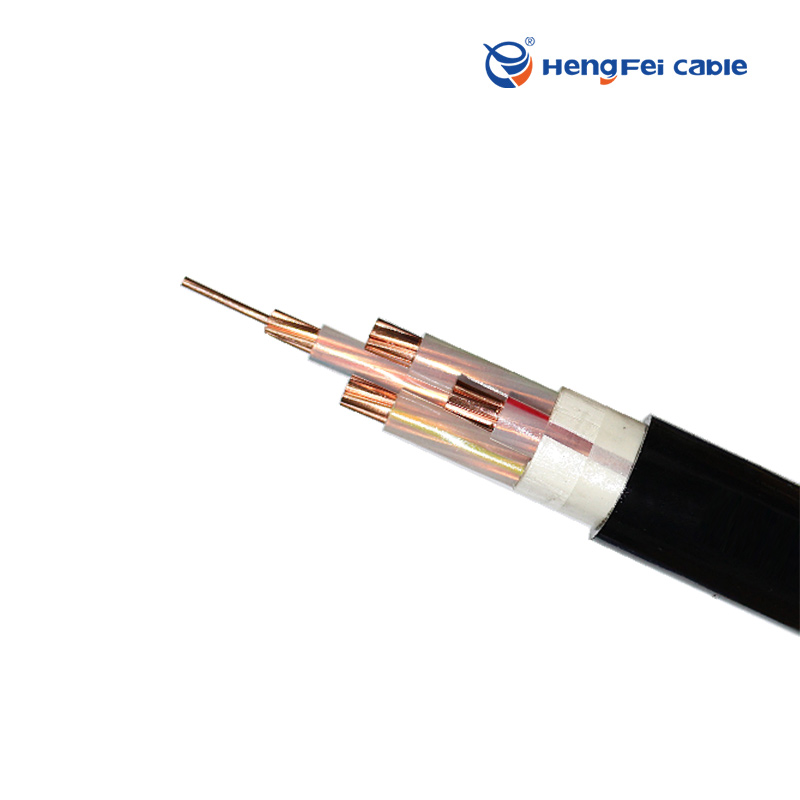

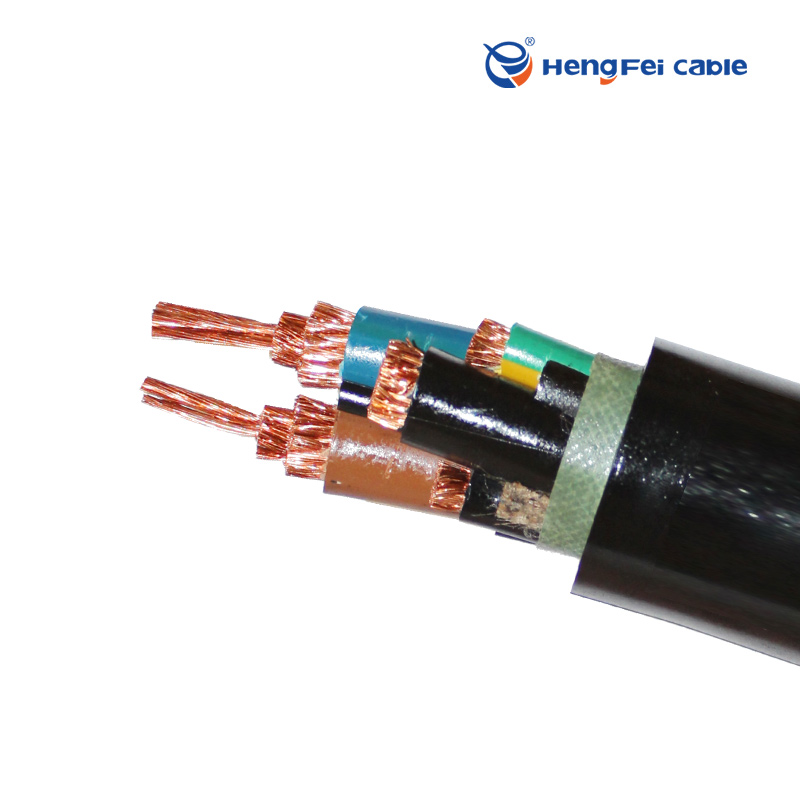

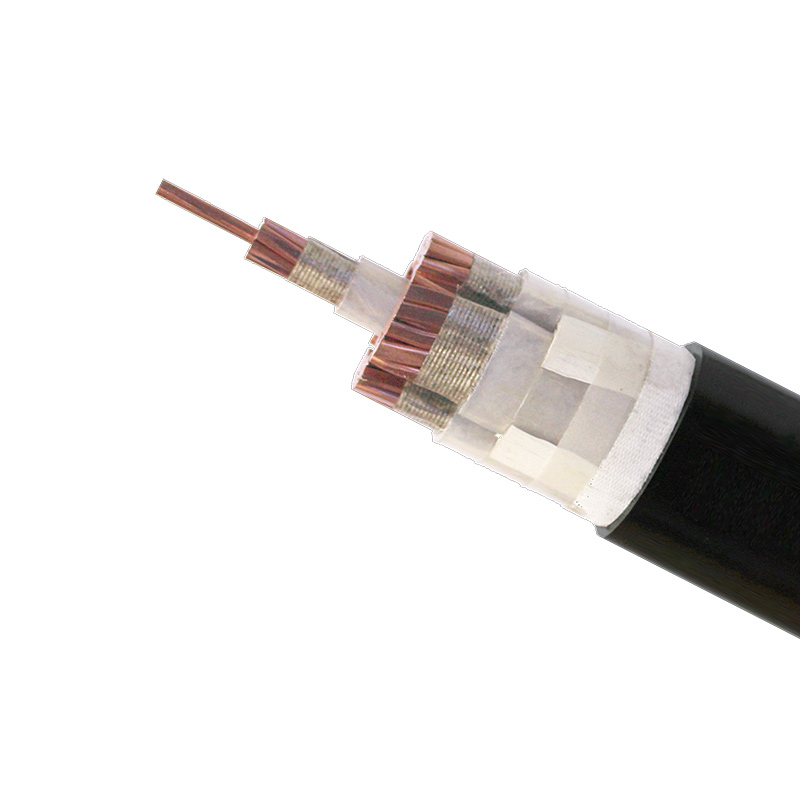

1. Conductors: The Heart of the Cable

The conductor is the core part of the cable that actually carries electricity. Two metals dominate this space:

Copper

Copper is the gold standard (well, almost literally) when it comes to electrical performance.

Pros:

-

Excellent conductivity

-

Strong and flexible

-

Resistant to corrosion

Cons:

-

More expensive than alternatives

-

Heavier, making it harder to install

Best for: Permanent installations, high-load systems, or where reliability is critical.

Aluminum

Aluminum is often used in power distribution where weight and cost matter.

Pros:

-

Lightweight (great for overhead lines)

-

More affordable

Cons:

-

Less conductive than copper (you need thicker cables)

-

More prone to oxidation and breakage

Best for: Utility lines, long-distance transmission, and budget-sensitive projects.

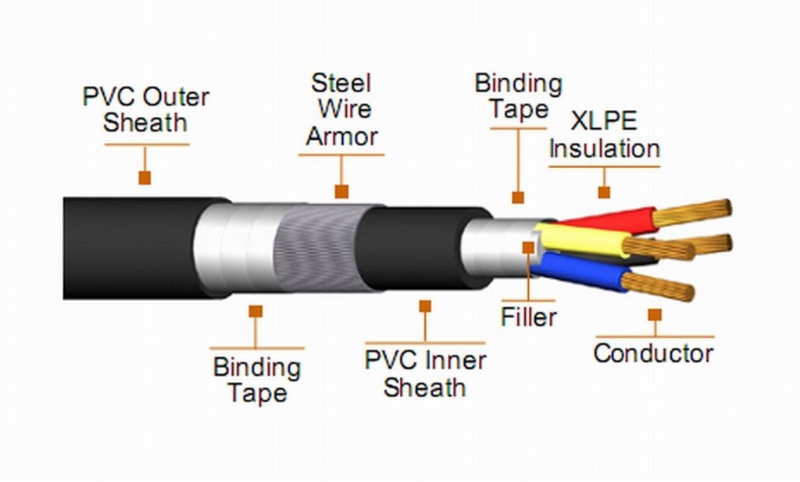

2. Insulation: Keeping the Electricity Where It Belongs

Insulation materials cover the conductor to prevent shocks, short circuits, and energy loss.

PVC (Polyvinyl Chloride)

One of the most common and cost-effective insulation materials.

Pros:

-

Inexpensive

-

Flame-retardant

-

Easy to work with

Cons:

-

Limited to lower temperature use (up to ~90°C)

-

Releases toxic gases when burned

Best for: Household wiring, small appliances, and light-duty use.

XLPE (Cross-linked Polyethylene)

This material is used when performance and heat resistance are required.

Pros:

-

High thermal and electrical performance

-

Resistant to chemicals and moisture

Cons:

-

More costly than PVC

-

Water-treeing can occur if not shielded properly

Best for: Industrial systems, high-voltage cables, and underground installations.

Rubber (EPR, Neoprene, etc.)

Flexible and rugged—ideal for mobile or temporary setups.

Pros:

-

Excellent flexibility

-

Great heat and abrasion resistance

Cons:

-

Heavier than plastic options

-

Higher price point

Best for: Extension cords, mining cables, portable power systems.

3. Sheathing: The Outer Armor

The sheath, or outer jacket, protects the entire cable from environmental and mechanical damage.

PVC (again!)

Used not just for insulation but also for outer sheathing.

Pros:

-

Economical

-

Moisture- and flame-resistant

Cons:

-

Doesn’t hold up well under UV or extreme heat

-

Becomes brittle over time

Best for: Indoor environments or where cost-efficiency is key.

LSZH (Low Smoke Zero Halogen)

A safer choice for confined spaces where fire risk is a concern.

Pros:

-

Minimal smoke/toxic gas in case of fire

-

Flame-retardant

Cons:

-

More expensive

-

Slightly stiffer than PVC

Best for: Data centers, transit systems, tunnels, and buildings with strict fire codes.

PE (Polyethylene)

Durable and moisture-resistant, but flammable.

Pros:

-

Excellent for outdoor or underground use

-

Chemically stable

Cons:

-

Not flame-retardant unless treated

-

Stiff in low temperatures

Best for: Direct burial, outdoor applications, oil & gas environments.

Final Thoughts

There’s no one-size-fits-all material when it comes to power cables. Each component—conductor, insulation, and sheathing—is chosen based on the demands of the project: temperature, voltage, environment, safety, and budget.

If you're planning an installation or just trying to understand what's behind your walls, knowing the strengths and weaknesses of cable materials helps ensure better performance, durability, and safety.

Quick Tip:

Always check national codes and regulations before selecting cable types—especially for commercial or high-voltage installations.