Understanding Current-Carrying Capacity: Beyond Just Wire Gauge

When choosing electrical conductors, many people assume that wire gauge alone determines how much current a wire can safely carry. While conductor size is important, it’s only one part of the equation. The actual current-carrying capacity (ampacity) of a wire is influenced by several factors, including insulation type, conductor material, ambient temperature, conduit fill, and even the ratings of connected terminals. Selecting the right combination of these elements is essential for both safety and performance.

Ampacity, or a wire's current-carrying capacity, is determined by more than just its gauge. The maximum current a conductor can safely carry depends heavily on factors that affect its ability to dissipate heat. Overheating from exceeding ampacity can damage a conductor's insulation and poses a serious fire risk.

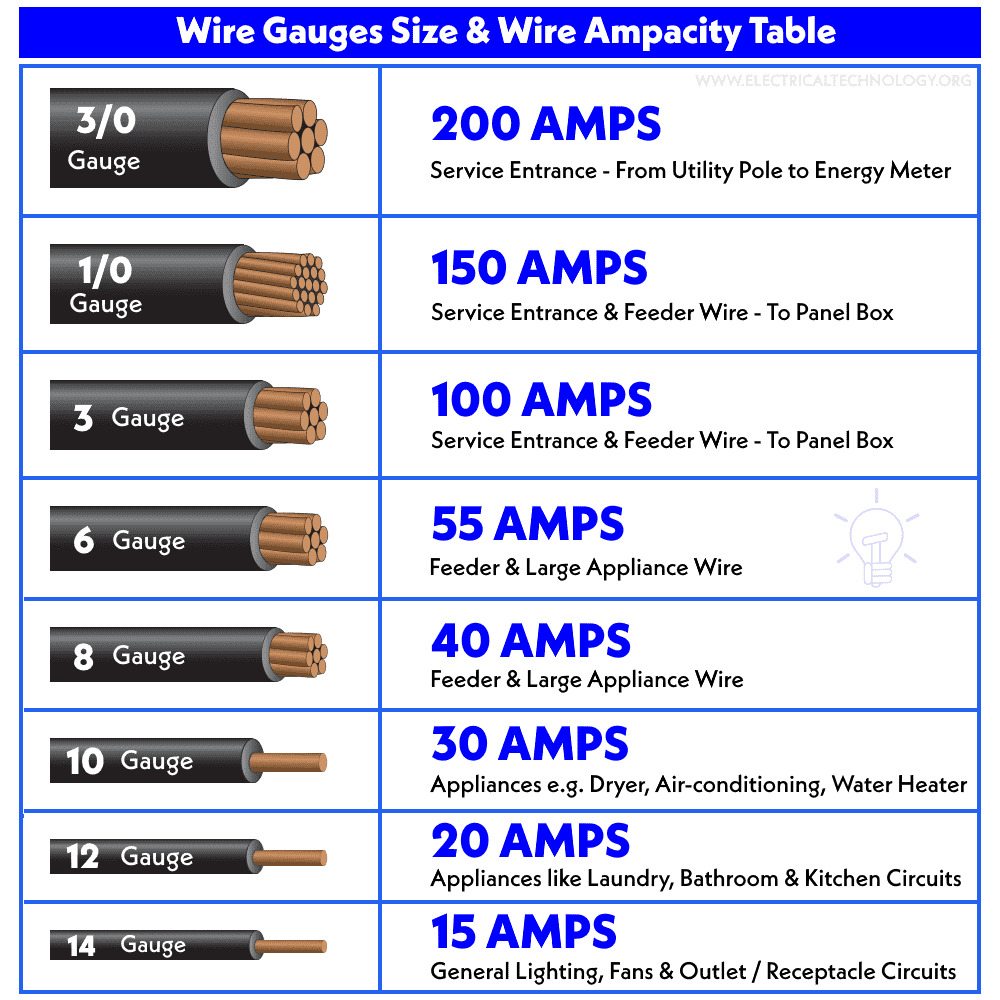

1. Wire Gauge (Cross-Sectional Area)

Wire gauge, or the cross-sectional area of the conductor, is the primary factor in determining resistance and heating. Larger wires have lower resistance and can carry more current. However, gauge alone does not guarantee safe ampacity, as the environment and materials involved can change the limits dramatically.

2. Conductor Material

-

Copper – High conductivity, standard choice, allows smaller wire sizes for the same ampacity.

-

Aluminum – Lighter and cheaper, but less conductive; requires a larger cross-sectional area for the same current.

-

Tinned Copper or Alloys – Used in specific environments for corrosion resistance.

Rule of thumb: Aluminum conductors need ~50% larger cross-section compared to copper to achieve similar ampacity.

3. Insulation Rating

The insulation around a conductor determines the maximum operating temperature the wire can withstand safely. Common ratings include:

-

60 °C – Older thermoplastic insulations.

-

75 °C – Many residential and commercial wiring types.

-

90 °C – High-performance insulations like THHN/THWN-2.

-

125 °C and above – Specialty wires for industrial or automotive use.

The higher the insulation rating, the greater the allowable ampacity, since the conductor can operate at higher temperatures without damaging the insulation.

4. Ambient Temperature

Ampacity tables usually assume a baseline ambient temperature of 30 °C (86 °F). When wires operate in hotter environments (e.g., rooftops, attics, industrial plants), derating is required. For example, a wire rated for 30 A at 30 °C may only be safe for 24 A at 45 °C.

5. Conduit or Cable Fill

When multiple conductors share the same conduit or raceway, they generate heat and restrict airflow. This raises operating temperatures and requires derating ampacity. For example, if more than three current-carrying conductors are installed together, the NEC (National Electrical Code) mandates applying a derating factor based on the total number of wires.

6. Terminal Ratings and Equipment Limits

Even if a conductor and its insulation are rated for high current, the weakest link in the system may be the terminals or connectors. For example, many circuit breakers, switches, and receptacles are only rated for 60 °C or 75 °C terminations. This means the wire must be sized not just for its ampacity but also for the terminal’s temperature rating.

7. Installation Conditions

Other installation factors can further impact ampacity, such as:

-

Altitude – Reduced cooling at higher elevations.

-

Bundling – Multiple cables tied together reduce heat dissipation.

-

Exposure – Direct sunlight or corrosive environments may demand specialized insulation.

Ampacity Reference Table (Copper Conductors, Single-Phase, 30 °C Ambient, NEC 310.16)

| AWG Size | Cross-Section (mm²) | 60 °C Insulation | 75 °C Insulation | 90 °C Insulation | Typical Applications |

| 14 AWG | 2.08 mm² | 15 A | 20 A | 25 A | Lighting, small loads |

| 12 AWG | 3.31 mm² | 20 A | 25 A | 30 A | General outlets, appliances |

| 10 AWG | 5.26 mm² | 30 A | 35 A | 40 A | Water heaters, dryers |

| 8 AWG | 8.37 mm² | 40 A | 50 A | 55 A | Ranges, sub-panels |

| 6 AWG | 13.3 mm² | 55 A | 65 A | 75 A | HVAC, feeders |

| 4 AWG | 21.2 mm² | 70 A | 85 A | 95 A | Large appliances, feeders |

| 2 AWG | 33.6 mm² | 95 A | 115 A | 130 A | Sub-panels, large HVAC |

| 1/0 AWG | 53.5 mm² | 125 A | 150 A | 170 A | Main service feeders |

| 4/0 AWG | 107.2 mm² | 180 A | 230 A | 260 A | Large service entrance, heavy feeders |

Note: Values assume copper conductors with no more than three current-carrying wires in conduit at 30 °C ambient. For higher ambient temperatures or conduit fill, apply NEC derating factors.

Example: A #10 AWG Copper Wire

-

Rated for 30 A in standard conditions (THHN insulation, 30 °C).

-

In a hot attic at 45 °C, derating reduces capacity to about 24 A.

-

If bundled with several other conductors in conduit, ampacity may drop further to 21 A or less.

Conclusion

The current-carrying capacity of a wire is not determined by wire gauge alone. Conductor material, insulation type, ambient temperature, conduit fill, and terminal ratings all interact to define safe ampacity. Electrical codes like the NEC (USA), IEC (international), and local regulations provide detailed ampacity tables and derating factors that engineers and electricians must follow.

When sizing conductors, always account for the weakest link in the system and apply derating factors for the actual installation environment. This ensures both electrical safety and long-term system reliability.